SYNERGi Sprint Automated Cells

SYNERGi Sprint cells are more compact and have smaller footprint than SYNERGi Premier and Classic and are ideal for the automated manufacture of smaller parts.

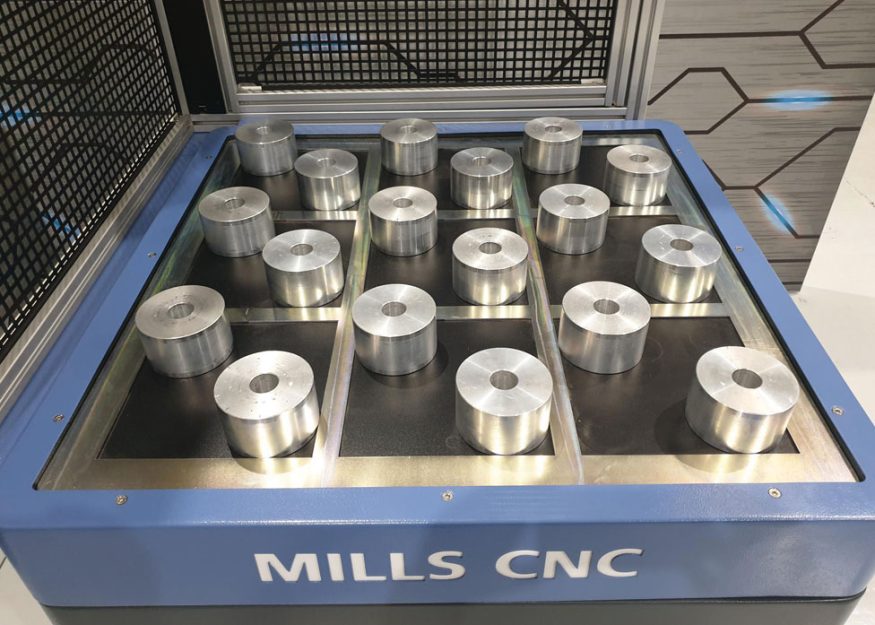

SYNERGi Sprint cells have a loading pattern (tray) system (900mm x 900mm) that uses grid plates for exact part positioning and location. Recommended maximum weight per gripper is 10kg.

These automated cells are powered by our own proprietary (SYNERGi) software and, at the heart of every system, is a sophisticated and intuitive HMI that incorporates a wide-range quality control, monitoring and inspection features and capabilities.

System Features

SYNERGi Sprint systems feature a 6-axis industrial robot, a loading/unloading tray system, a 17” touchscreen HMI, locating plates, pneumatic 2- or 3- jaw grippers, integrated SICK safety systems and industrial fencing, an interface for Heidenhain, Fanuc and Siemens control systems and a part turnover station.

Options include: multi-socket and component stacking systems.

Technical Specification

Standard System

| Robot |

Fanuc 6-axis: 25kg payload |

| Loading tray system |

900mm x 900mm |

| HMI |

17” touchscreen (separate keyboard) |

| Safety Systems |

SICK integrated systems |

| Software |

SYNERGi software Turnaround system Interface for Heidenhain, Fanuc and Siemens control |

| Options |

Multi-socket system Component stacking system |

Interested In Industrial Robots? Get In Touch

Contact the team at Mills CNC to find out about our SYNERGi systems, or to get more details about industrial robot solutions.