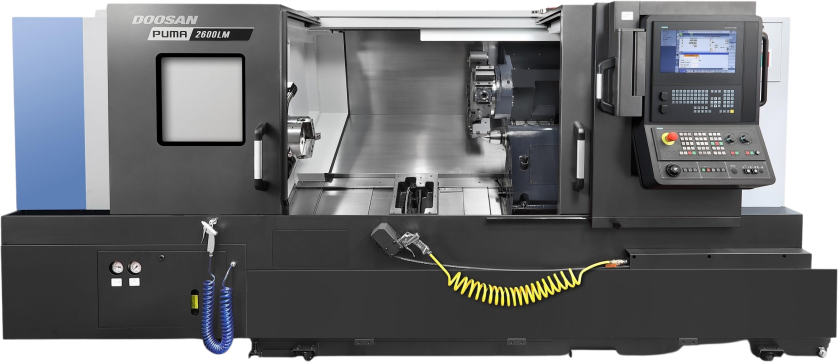

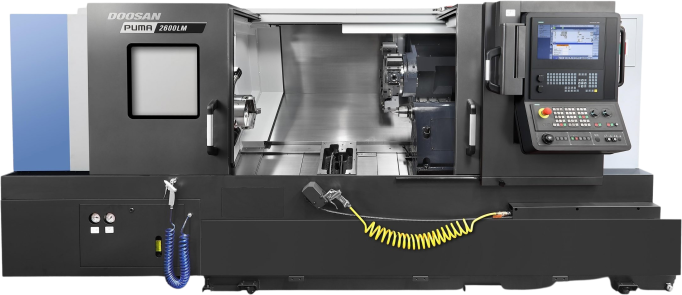

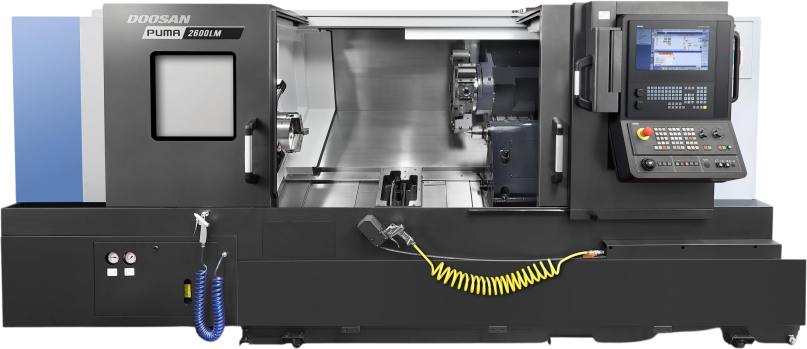

Puma 2600 Series

DN Solutions (formerly Doosan) Puma 2600 series lathes

Features

- 10″/12″ chuck / 76mm bar capacity

- Driven tooling (7.5kW/5000rpm)

- 105mm Y-axis stroke

- Long bed models available

or copy link

Puma 2600 lathes are the number one choice for component manufacturers looking for proven turning performance. All machines in the range deliver increased accuracies and repeatability’s, superior cutting performance and greater process reliability.

The box guide-way machines have a 10″/12″ chuck/76mm bar capacity, and are available in two bed lengths – 755mm and 1275mm.

In addition to their impressive technical specifications, Puma 2600 lathes are supplied by Mills with: Automatic Tool Setters, Parts Catchers, tailstocks (for non- sub-spindle machines), and the Manual Guide/Conversational Programming System, as standard.

There are six different models in each bed length and manufacturers can select Puma 2600 machines with sub-spindles, driven tools, C-axes and Y-axes.

Technical Specification

| Chuck size | 10 - 12inch |

|---|---|

| Max. Turning Diameter | 376 - 481mm |

| Max. Turning Length | 520 - 1310mm |

| X Axis Rapid Traverse | 30m/min |

| Z Axis Rapid Traverse | 30m/min |

| Max. Spindle Speed | 2800 - 4000r/min |

| Max. Spindle Power | 18 - 22kW |

| Max. Spindle Torque | 235 - 1123N·m |

| No. of tool station | 12 - 24 |

| X Axis Travel distance | 260mm |

| Y Axis Travel distance | 105mm |

| Z Axis Travel distance | 590 - 1350mm |

| Bar Capacity | 76 - 81mm |

| Rotary Tool r/min | 5000r/min |

| Max. Sub Spindle Speed | 4500 - 6000r/min |

| Max. Sub Spindle Power | 7 - 15kW |

Series Dimensions

| Length | 3415 - 4438mm |

|---|---|

| Width | 1863 - 2049mm |

| Height | 1900 - 2163mm |

| Weight | 4900 - 7950kg |

Image representative of Series and may not be the exact model

The Puma 2600 Series is compatible with Fanuc and Siemens.

The Mills CNC Projects' Team, incorporating experienced engineers, will undertake a site survey and create a tailored machine delivery and installation plan that is pre-agreed with customers.

The project team will then manage the whole process and act as a seamless interface between the customer, Mills CNC and any required 3rd party specialist service providers through delivery, installation and commissioning of the machine

Talk to Mills about this series

Whether you’re ready to order or want some more details about this product, fill out our enquiry form and we’ll get right back to you.

"*" indicates required fields

Related Case Studies

Focus. Drive. And ambition.

Puma 2600SY Horizontal Single Turret Lathe

Macro Manufacturing’s latest CNC machine tool investment significantly increases the company’s machining capacity and capabilities, and underlines its ambitious growth plans for the future.

On a journey toward sustainable machining

Puma 2600SY II Horizontal Single Turret Lathe

Sustainable machining pioneers MCS invest in a new DN Solutions Puma 2600SY II sub-spindle, Y-axis lathe, and a Puma TT1800SY twin-turret turning centre for improved reliability and performance, and to expand capacity at their Redditch manufacturing centre.

Commitment to continuous improvement drives latest machine tool investment for DRB Group.

Doosan Puma 2600LY II Lathe Machine

Deeside based DRB Group has a focus on the repair, maintenance & supply of electric motors, generators and mechanical transmission systems to customers in the rail, pharmaceutical, food & beverage, medical and energy sectors. DRB recently invested in a Doosan Puma 2600LY II Lathe Machine from Mills CNC to improve machining capabilities.

Related Series from CNC Horizontal Single Turret Lathes

Why choose Mills CNC

Why choose Mills CNC

Mills CNC are much more than just a Doosan distributor, our services and support ensure that you can get exactly what you need from financing options to training for your team.

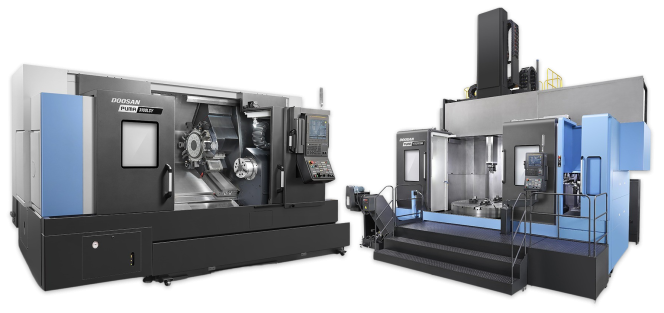

CNC Solutions

Not sure what you need? Mills CNC can help you incorporate your DNM 200 5AX into a turnkey or automated solution that works perfectly for your business.

CNC Automation Systems

From automated Cobots providing machine tending operations, to a bespoke system of sensors, controls and actuators to automate a manufacturing process, Mills CNC can provide an efficient, effective automation solution for you.

Turnkey Solutions

A turnkey solution is more than just a machine, it’s a full service solution that ensures that your CNC setup is perfectly tailored to your manufacturing needs. This can often include automation for a fully streamlined process.

Not Sure What You Need? Get In Touch

If you’re not certain what machine is right for your needs, then Mills can point you in the right direction. Tell us about your requirements, and we can suggest the right series, machine or additional options that will work best for you.