Leading precision subcontract specialist, Barrs Court Engineering, invests in a new DN Solutions’ DNM 6700 vertical machining centre from Mills CNC to increase its in-house milling capacity and capabilities, and both strengthen and grow its High-Mix, Low-Volume (HMLV) parts processing operation.

Mills CNC, the exclusive distributor of DN Solutions’ and Zayer machine tools in the UK and Ireland, has recently supplied Barrs Court Engineering Ltd., a leading precision machining and fabrication subcontract specialist based in Herefordshire, with a new high-performance vertical machining centre.

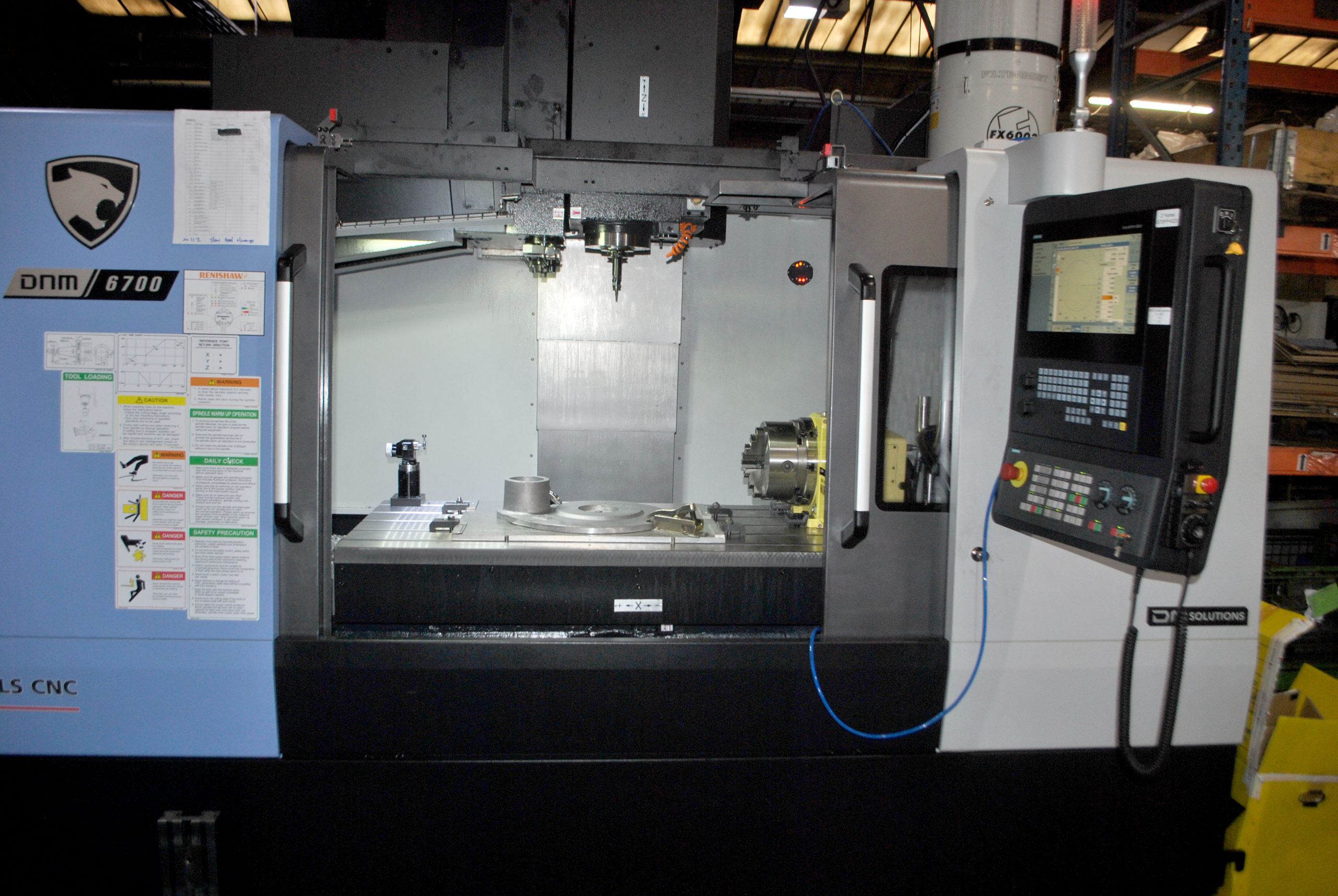

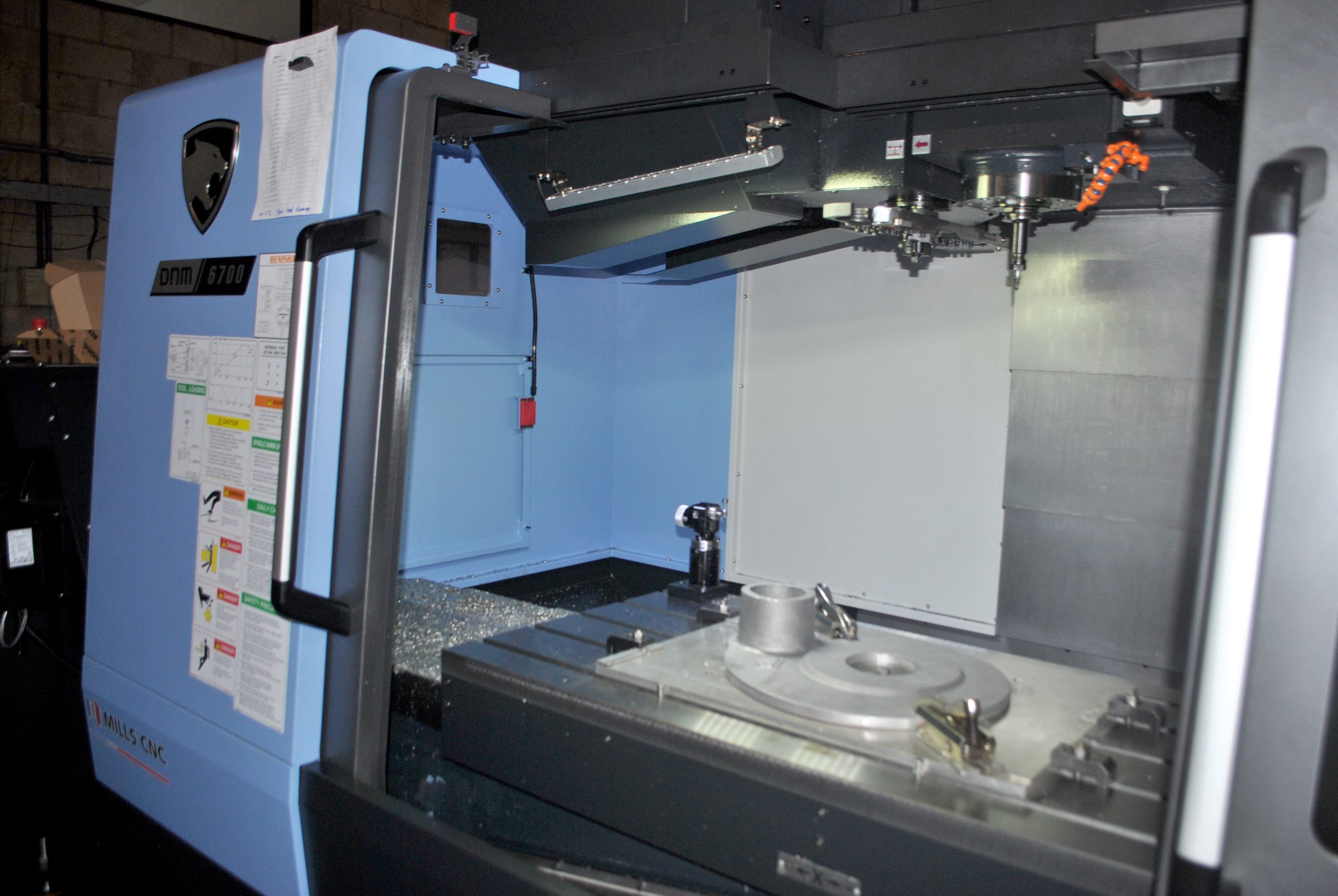

The machine, a DN Solutions’ Siemens 828D controlled DNM 6700, was installed at the company’s 11,500sq. ft. facility in Rotherwas in June 2024 and is being used to machine high-precision complex parts, in low volumes, for a range of customers in the marine, renewables, nuclear, steam, automotive and yellow goods/construction sectors…to name but a few.

These parts, machined from a range of materials that include aluminium, mild steel, stainless steels, cast iron, Inconel, exotics, plastics etc., are characterised by their tight tied- up tolerances and exacting surface finishes.

The DNM 6700 is also being used to finish-machine fabricated parts made by the company prior to their assembly.

Barrs Court Engineering, established in 1983, regularly invests in new, advanced machine tools as part of a rolling, company-wide continuous improvement programme designed to increase the company’s productivity, performance and process efficiencies across all of its machining operations, and is no stranger to technologies supplied by Mills CNC.

In 2001, Barrs Court Engineering invested in its first Doosan lathe (a Puma 300) and, in addition to purchasing a number of other manufacturers’ machines over the years, has also acquired a sub-spindle, Y-axis turning centre from Mills CNC to strengthen its in-house turning capacity and capabilities: the DNM 6700 is, however, the first milling machine the company has acquired from Mills in its 41-year history.

A watershed moment

Almost 12-months ago, Barrs Court Engineering began a strategic process of rationalising and streamlining its business by creating three discrete machining areas in its machine shop – each one focused on a specific production model designed to meet different customer’s machining needs and requirements.

“The new manufacturing strategy is focused on growth, and has imposed a discipline across all our planning and production operations.

“We analysed our existing business, including what our customers expected and demanded from us, and identified three different production ‘models’ which would direct how we would organise our machine shop and manufacturing operations i.e., the allocation of resources (people, technology etc.), moving forwards.”

Toby Kinnaird, Managing Director at Barrs Court Engineering

The three models

Low Mix – High-Volume parts production

Barrs Court Engineering has at its disposal a number of dedicated machine tools with integrated automation (i.e., pallet changers and bar feeders) for its LMHV manufacturing operation which is, to a large extent, predictable in nature and is characterised by ‘scheduled’ repeat business from customers.

This ‘production-type’ work with its emphasis on small-to-medium batch production (i.e., 20-off to 1000-off), has a number of critical success factors – mainly the ability to machine quality parts cost-efficiently and to customers’ often stringent delivery schedules.

High Mix – Low Volume parts production

Manufacturing bespoke, high-quality components in small batches (i.e., one-offs), has always been a particular strength of Barrs Court Engineering, and is perceived as a high growth area for the company.

Often requiring a ‘turnkey’ approach with machined parts characterised by their high-precision, complexity and long cycle times, the company specifically acquired the new DNM 6700 machining centre to strengthen its performance in this high-value production area.

Job shop production

For those customers requiring immediate access to high-quality machining services, Barrs Court Engineering runs a discrete job shop facility – separate from its LMHV and HMLV operations.

The availability of dedicated machines and staff to operate these machines ensures that there is always capacity available to handle ‘rush’ work quickly, effectively and profitably without compromising operational efficiencies or the performance of its other (two) machining areas.

To support the creation of these different models, Barrs Court Engineering has invested in new production software to increase its productivity, improve efficiencies and deploy its resources more effectively. This move is already paying dividends.

Improved planning and performance-monitoring in real time, using ERP software and the ability to generate, collect and visualise meaningful data, has been (and continues to be) instrumental in helping the company identify production ‘pinch-points’ and bottlenecks which, if not addressed quickly or satisfactorily, could affect future productivity, lead time fulfilment and profitability etc,

The DNM 6700 investment rationale

“To increase our HMLV machining capacity and capabilities we made the decision, at the beginning of the year, to invest in a new high-performance machining centre to replace two of our older machines that had limited capacity.

“We were particularly looking for a machine with a larger X-axis to handle bigger parts which, up until then, and from a capacity perspective, had been out of our reach.”

Toby Kinnaird, Managing Director at Barrs Court Engineering

The DNM 6700 has a large working envelope and with its 1300mm x 670mm x 625mm X/Y/Z-axis travels can be used to machine large components and/or multiple smaller parts in a single set up.

Barrs Court Engineering compiled a ‘must have’ technical checklist for its future machining centre investment and visited MACH 2024 Show in April to identify a suitable machine.

“We visited Mills CNC’s stand on the first day of the Show, and discussed our requirements with their sales staff. They provided details on the DNM 6700 that was in stock at their Leamington facility and which, as a consequence, would be available for immediate delivery.

“After a short while negotiating the deal, we placed the order for the machine later that week.”

Toby Kinnaird, Managing Director at Barrs Court Engineering

The DNM 6700 – a closer look

The DNM 6700 is a large-capacity vertical machining centre.

The model acquired by Barrs Court Engineering is equipped with the 828D Siemens control, with ShopMill software, and features a powerful 18.5kW/ 12,000rpm (117.8N-m) directly-coupled spindle, a 1500mm x 670mm worktable (with 1300kg table load), and a 40-tool position ATC.

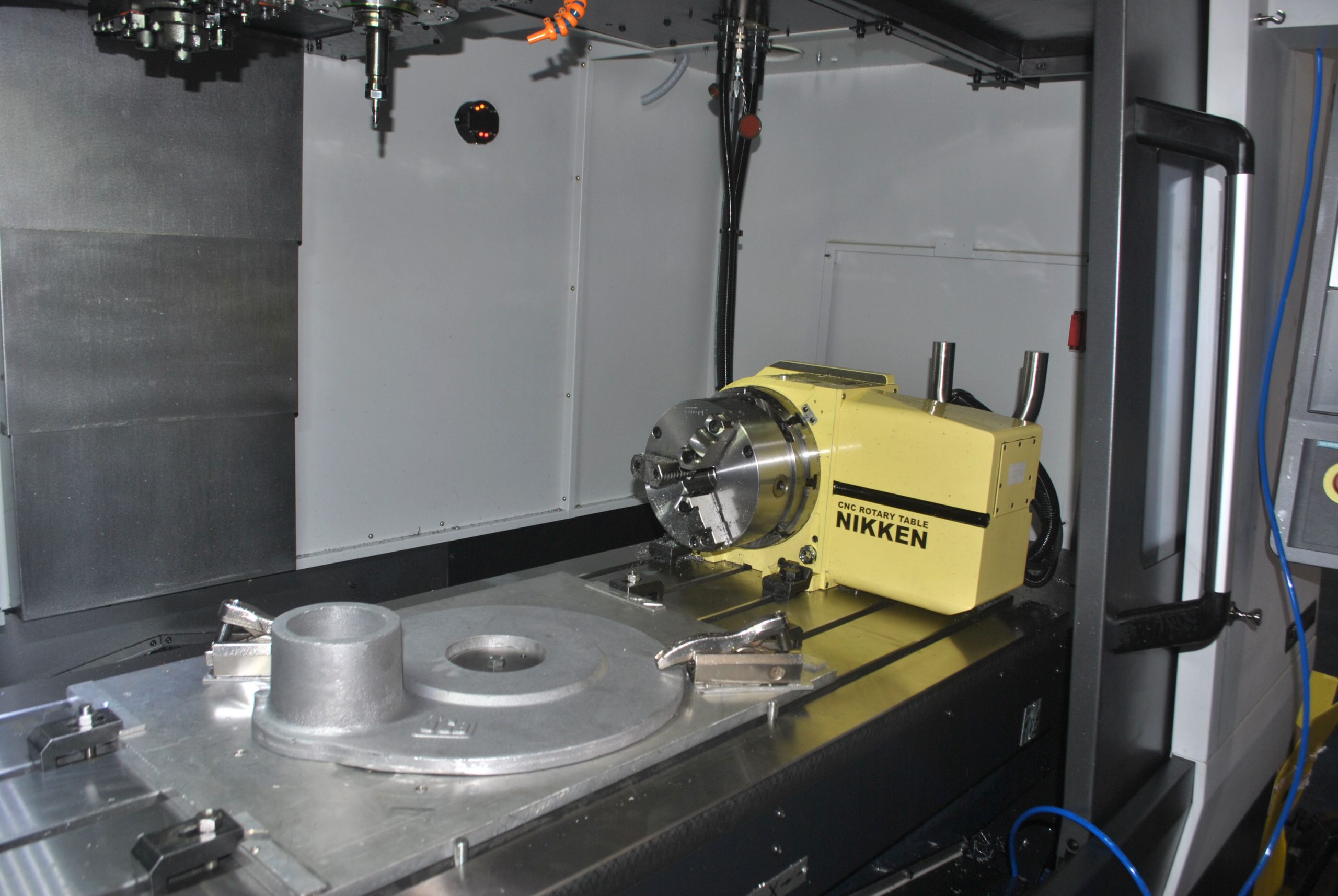

The machine delivered and installed also includes through-spindle-coolant capability (20bar), Renishaw RMP and RTS (Radio Transmission Workpiece and Tool Setting) probes, a FilterMist oil mist extraction unit, a high-efficiency swarf conveyor and a Nikken CNC 260 (4th-axis) rotary table.

“Our new DNM 6700 is powerful, fast, accurate and flexible. The Siemens Control is intuitive and is easy to use, making programming and job setups quicker and more accurate.

“The integration of the 4th-axis table enables us to machine complex parts with intricate features in a single setup, avoiding the time and cost involved in re-fixturing operations and the potential for losing accuracy, and the inclusion of Renishaw workpiece and tool probes improves process efficiencies, ensures part quality and facilitates in-process measurement.

“We are delighted with our new investment and are confident that the machine, backed by Mills’ best-in-class after-sales services and support, will help us grow our business in the future.”

Toby Kinnaird, Managing Director at Barrs Court Engineering

In addition to buying the machine from Mills CNC, Barrs Court Engineering has also taken advantage of a number of Mills’ pre- and after-sales services.

Mills CNC Finance was used to help finance the machine purchase, Mills CNC Training Academy has been used to train (remotely and on-site) designated members of staff to ensure the company gets the most from their machine purchase, and Barrs Court Engineering has also taken out a Mills CNC Service Agreement on the DNM 6700 to ensure its performance is optimised via regular and planned servicing interventions.

About Barrs Court Engineering

Established in 1983, Barrs Court Engineering is a family-owned business that today employs nine members of staff.

The company originally started out as a machine shop machining agricultural equipment and lubrication components for a handful of customers.

Since then the company has grown exponentially, twice relocating to new, larger premises, investing in numerous CNC machine tools along the way and adding fabrication and assembly to the services it provides.

The company has a strong commitment to continuous improvement and regularly invests in its people, in its plant and equipment and in its processes and systems.

Barrs Court is an advocate of automation, and as well as investing in multi-tasking CNC machine tools, has also improved its fabrication operation through acquiring cobot welding technology in 2023: the company is also actively looking to invest in cobot polishing in the near future.

Other investments (i.e., improving its CAD-CAM capabilities) are planned, and the acquisition of more sophisticated machine tools to replace existing, older machines are also in the pipeline too.

The company operates an in-house apprenticeship programme in conjunction with a local FE College and Training Provider and, through its managing director, has been more than instrumental in setting up NMITE (New Model Institute for Technology and Education), a Higher Education Institution specialising in integrated engineering located in Hereford.

Barrs Court Engineering is a company with ambitious plans for the future. The re-organisation of its machine shop and the acquisition of new, advanced machine tool technologies are evidence of its commitment to improvement and growth.