Innovative turnkey solution provides leading forklift truck manufacturer with improved flexibility and process reliability.

Mills CNC, the exclusive distributor of Doosan machine tools in the UK and Ireland, and home of the CNC Training Academy, is increasingly being approached by manufacturers to help design and implement what, in many instances are, innovative manufacturing turnkey and process improvement solutions.

A recent example of Mills’ turnkey expertise and the way it works collaboratively with customers to create and deliver optimum solutions is in evidence at the Northern Irish forklift truck manufacturing site of US-owned NACCO Materials Handling Group (NMHG).

Located in Craigavon in Country Armagh since 1981, NMHG’s manufacturing operation is extensive and is the largest electric and ICE (internal combustion engine) counterbalanced forklift truck production site in the UK.

Up to 14,000 Hyster® and Yale® branded forklifts are manufactured each year at the Craigavon plant – a good 80% of which are exported to Europe, Russia, Africa and the Middle East.

Hydraulic cylinder manufacture

As part of its on-going quality and continuous improvement programmes NMHG undertook a thorough review of its in-house Hydraulic Cylinder Manufacturing facility in 2012.

This facility, first opened in 1996, manufactures hydraulic cylinder parts (essentially different length and diameter tubes and rods) for its 1 – 2 tonne and 2 – 3.5 tonne trucks, and is run on JIT and Lean Manufacturing principles.

The manufacturing process used by NMHG to make the hydraulic cylinders had been developed almost 20 years ago and although still meeting part accuracy and cycle time requirements was, owing mainly to difficulties in obtaining spares and parts, becoming more unreliable.

Explains Rodney Kerr, Projects Superintendent at NMHG:

“Downtime in any of our manufacturing processes creates unwanted bottlenecks and affects efficiencies all across our manufacturing, fabrication and assembly operations.

“To prevent our hydraulic cylinder plant becoming a weak link in our manufacturing chain we approached a number of companies to recommend a new, improved and upgraded process that would meet our existing and future capacity requirements.”

Mills CNC was one of the companies approached.

The existing process

To fully appreciate the innovative solution proposed by Mills CNC (and subsequently approved), it is important to understand the original production process used by NMHG to manufacture its tubes and rods.

The process for each was automated and consisted of a twin-spindle, single turret lathe and two bar loaders located at either end of the machine. Pre-cut tubes or rods were fed into the lathe and machined on one end using different milling, threading and turning tools to achieve the required features.

Once completed the tubes or rods were then ‘drawn’ through the machine…held in the second (opposing) spindle for machining on the tubes’ or rods’ back ends before being moved out of the lathe into the second bar loader and then, subsequently, onto secondary operations (i.e. washing etc.).

When working at full capacity (with no interruptions or downtime) this linear manufacturing process was fast and was able to produce 300 rods and 300 tubes per day.

NMHG’s requirement

NHMG put the upgrade of its Hydraulic Cylinder Manufacturing plant out to tender and invited a number of companies to prepare and submit proposals.

Explains Rodney Kerr:

“We needed to maintain production capacity (so part cycle times needed to be maintained), and also wanted the new process to be more flexible enabling us, in the future, to handle larger diameter bar (for larger hydraulic cylinders on larger forklift trucks).

“We anticipated that the proposals we received would essentially be larger and more sophisticated versions of what we already had…but Mills approached the challenge differently and captured our imagination.”

Mills CNC’s proposal

The turnkey solution proposed by Mills focused on the creation of two flexible and dedicated robotic manufacturing cells.

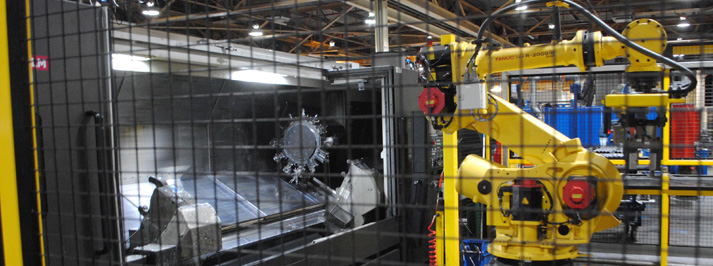

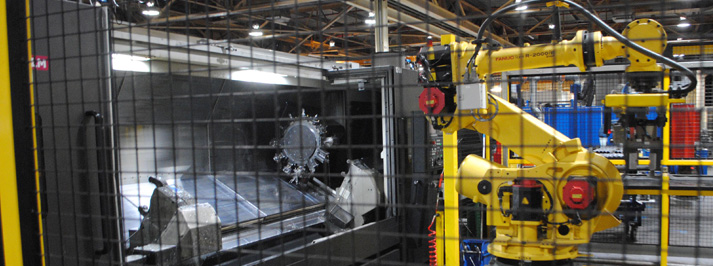

Both cells – one used to manufacture hydraulic cylinder tubes and the other hydraulic cylinder rods – were similar with each featuring a new Doosan Puma 3100ULM long bed, single-spindle lathe with driven tools, a Fanuc R2000iB-210 6-axis robot, Fanuc Cell Management software and Renishaw laser measurement and probing systems etc.

Instead of parts being ‘drawn’ through the lathe as was previously the case – tubes and rods would be picked up by Fanuc robots’ arms having first been checked and inspected by Renishaw inspection equipment to ensure that the right length and diameter parts were in place.

After correct part identification had occurred, the tubes and rods would be loaded into the Puma 3100ULM lathes – through their doors – which were automatically controlled by the Fanuc Cell Management software.

Once positioned in the spindle the part, with its protruding end supported in an adjacent bar feeder, would be machined using the same cutting data (speeds/feeds/depths of cut), as well as the same cutting tools, fluids, spindle tooling etc.

After machining one end of the part, the machines’ doors would open automatically and the robot would take the part out of the machine, reorient it and position it back in the spindle for the remaining end to be machined.

Once all machining operations had been performed, the robot would take the completed part out of the machine and position it on powered roller conveyors that would take it to be finished (i.e. washing).

Amongst the specific strengths of Mills’ proposed solution were the following:

- The cells had a compact footprint compared to any larger ‘linear’ manufacturing process that may have been proposed;

- Part cycle times using the Mills solution were proved to be just as quick as those achieved with the previously used process;

- All equipment in Mills’ flexible manufacturing cells were standard – which kept initial investment costs down and ensured that any spare and wear parts required in the future could be easily and cost-competitively sourced;

- The robotic cells were flexible and had capacity to handle larger diameter bars (tubes and rods);

Leap of faith?

Turnkey projects are often complex. From a customer’s perspective they can involve a number of different departments and key personnel – each with their own area of specialism and each having their own preferred solution.

Remembers Rodney Kerr:

“Mills’ proposed solution took us out of our comfort zones.

“However, Mills’ staff from sales managers through to pre-sales engineers and from applications through to service engineers – all helped put our minds at rest and did everything they could to ensure that any questions or reservations we had were answered.”

Mills’ expertise and business approach were also noted by Robert Woods, Head of Plant Maintenance:

“Mills’ positive approach combined with their engineers’ technical know-how and experience; their ability to create good working relationships with us based on transparency and integrity; their recently created Turnkey Development Centre in Leamington Spa (where they would develop, refine, test and prove out their solution for us); and the fact that they had applications and service engineers on the ground here in Northern Ireland – were also equally important.”

Key to overcoming any NMHG concerns was a visit set up by Mills to an existing customer who had recently invested in Doosan machine tools and Fanuc Robots.

Says Rodney Kerr:

“From talking to this customer and seeing the Manufacturing Cells in action we could quickly appreciate the productivity and performance benefits of the automated solution.”

Summary

Mills’ proposed turnkey solution may, at first glance, not have been anticipated but it was the solution that was required. Both manufacturing cells were installed in 2014 and have been operating more than satisfactorily ever since.

Concludes Alan Little, VP Manufacturing & Logistics, EMEA, NMHG:

“I have been very impressed with the integration and teamwork between our company, Mills CNC and in turn with Doosan & Fanuc. This was a very well planned and executed capital investment programme and we are very satisfied with the final product. I was particularly pleased with the commitment of Mills CNC to commit to and quickly resolve the few technical issues that any investment of this complexity inevitably has, to the complete satisfaction of us the customer.”