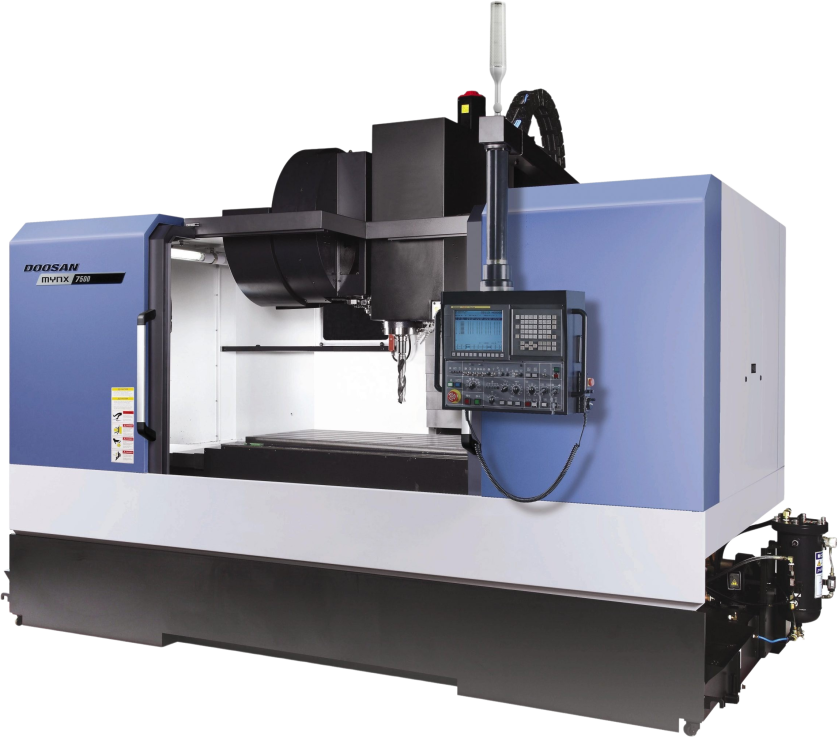

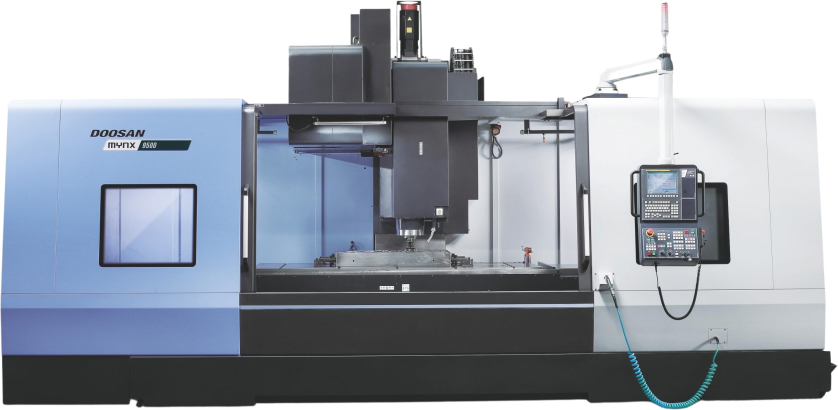

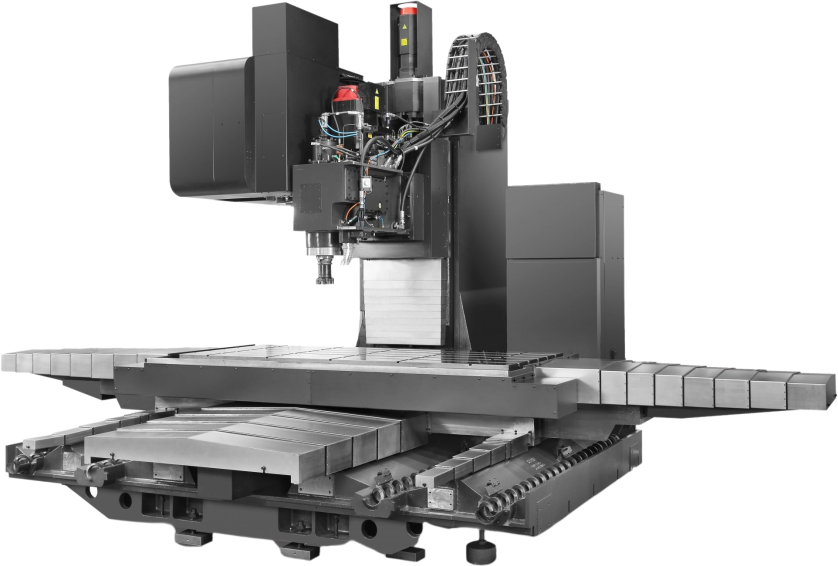

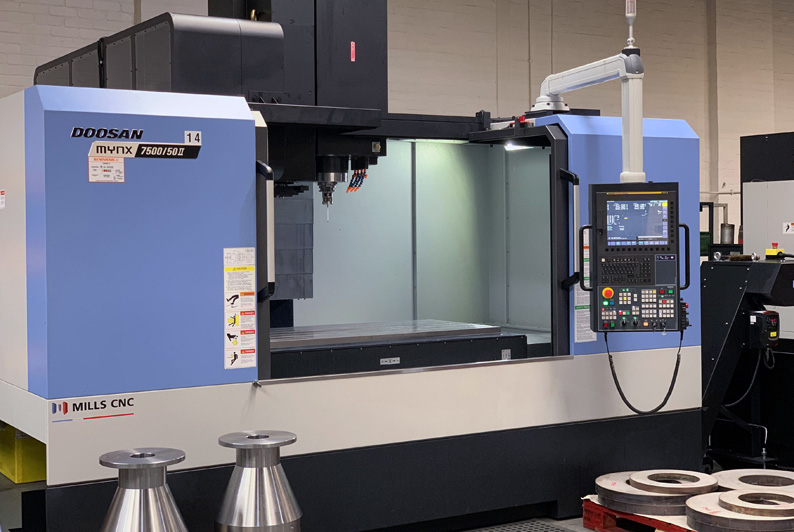

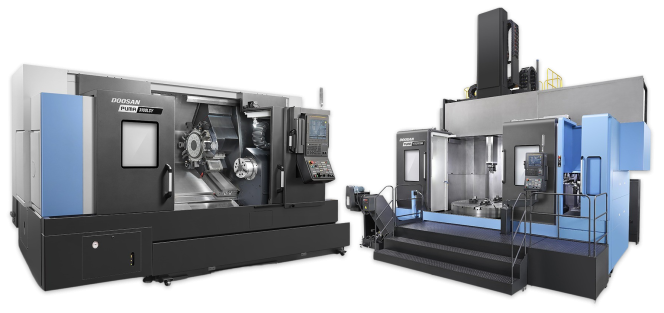

Mynx 7500/50 II

DN Solutions (formerly Doosan) Mynx 7500/50 II Vertical Machining Centre

or copy link

Technical Specification

| X Axis Travel distance | 1525 mm |

|---|---|

| Y Axis Travel distance | 770 mm |

| Z Axis Travel distance | 625 mm |

| X Axis Rapid Traverse | 30 m/min |

| Y Axis Rapid Traverse | 30 m/min |

| Z Axis Rapid Traverse | 24 m/min |

| Max. Spindle Speed | 8000 r/min |

| Max. Spindle Power | 30 kW |

| Max. Spindle Torque | 617.4 N·m |

| Table Length | 1600 mm |

| Table Width | 750 mm |

| Max. Table Weight | 1500 kg |

| No. of tool station | 30 |

Product Dimensions

| Length | 3900mm |

|---|---|

| Width | 4050mm |

| Height | 3235mm |

| Weight | 13500kg |

Image representative of Series and may not be the exact model

The Mynx 7500/50 II is compatible with Fanuc, Siemens and Heidenhain.

The Mills CNC Projects' Team, incorporating experienced engineers, will undertake a site survey and create a tailored machine delivery and installation plan that is pre-agreed with customers.

The project team will then manage the whole process and act as a seamless interface between the customer, Mills CNC and any required 3rd party specialist service providers through delivery, installation and commissioning of the machine

Talk to Mills about the Mynx 7500/50 II

Whether you’re ready to order or want some more details about this product, fill out our enquiry form and we’ll get right back to you.

"*" indicates required fields

Related Case Studies

Well prepared – for all eventualities.

Doosan Mynx 7500/50 II Vertical Machining Centre

Tyne & Wear based Washington Components, a subcontract specialist serving the oil & gas subsea sector, has invested in Two new machine tools. The 2nd acquisition, a Doosan Mynx 7500/50 large-capacity vertical machining centre demonstrates the depth and sophistication of machining operations required of subcontractors operating in the subsea, off-shore & wind energy markets.

Why choose Mills CNC

Why choose Mills CNC

Mills CNC are much more than just a Doosan distributor, our services and support ensure that you can get exactly what you need from financing options to training for your team.

CNC Solutions

Not sure what you need? Mills CNC can help you incorporate your DNM 200 5AX into a turnkey or automated solution that works perfectly for your business.

CNC Automation Systems

From automated Cobots providing machine tending operations, to a bespoke system of sensors, controls and actuators to automate a manufacturing process, Mills CNC can provide an efficient, effective automation solution for you.

Turnkey Solutions

A turnkey solution is more than just a machine, it’s a full service solution that ensures that your CNC setup is perfectly tailored to your manufacturing needs. This can often include automation for a fully streamlined process.

Not Sure What You Need? Get In Touch

If you’re not certain what machine is right for your needs, then Mills can point you in the right direction. Tell us about your requirements, and we can suggest the right series, machine or additional options that will work best for you.