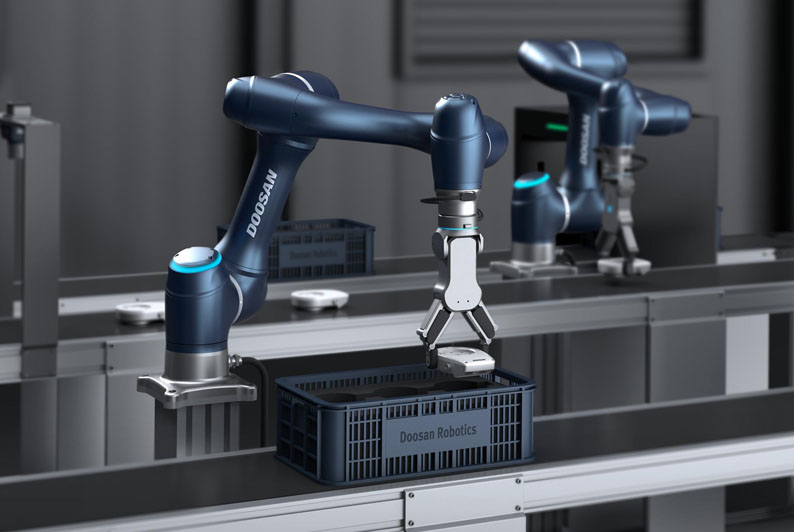

Latest Doosan Robotics’ cobots set new benchmarks in speed, versatility and safety.

Mills CNC Automation, a division of Mills CNC and the exclusive distributor of Doosan Robotic’s collaborative robots in the UK and Ireland, has recently introduced two new innovative cobot ranges (series) into the market.

The new A-series and H-series, comprising six new models in total, have significantly strengthened Mills CNC Automation’s cobot line-up and, in conjunction with the M-series (comprising four models) previously launched in 2018, will help Mills CNC Automation reinforce its market position and profile as the ‘go to’ specialist provider of collaborative robot technology systems and solutions.

A-series

The series comprises four different models: the A0509, A0509s, A0912 and A0912s, and boast a payload capacity from 5kg to 9kg, and a reach from 900mm to 1200mm.

A-series cobots feature an advanced safety algorithm that makes them ideal for operating in a wide range of manufacturing and production environments, and takes collision detection sensitivity and safety beyond existing levels.

The cobots are fast with impressive speed and acceleration characteristics. A-series’ joint (axis) speeds are twice that of competitor cobots currently available on the market.

Says Peter McCullough, Mills CNC Automation’s Product Manager (Doosan Robotics):

“Cobot operating and processing speeds are important. They help reduce cycle times and, as a consequence, improve customers’ productivity levels which, in turn, impacts (positively) on their ROI.”

Two of the A-series cobots (A0509s and A0912s) are equipped with force sensor technology which increases their application potential to include delicate tasks requiring ‘human- like’ dexterity such as polishing and intricate assembly operations.

H-series

There are two models in the series – the H2017 and the H2515. The H2017 has a payload capacity of 20kg and a reach radius of 1700mm, the H2515 has a payload capacity of 25kg and a reach radius of 1500mm.

Both models are equipped with six torque sensors integrated on their (6-axis) arms which if/when detecting any changes in force or pressure causes the cobots to stop in their tracks.

Continues Peter McCullough:

“Safety is critically important. Torque sensors help shut down the cobot immediately once torque thresholds have been exceeded, preventing injury to humans or to the cobot itself.”

New A-series and H-series cobots, along with existing M-series models are all available to view at Mills CNC’s, recently opened, Automation and Turkey Centre located at the company’s Campus facility in Leamington.

Concludes Peter McCullough:

“The cobot market is fiercely competitive. Many cobots on the market are very similar to one another and can be classed as ‘me too’ products.

“The new cobots from Doosan Robotics are innovative and different: they offer customers game changing, best-in-class speed, versatility and safety.”