Birds Precision Engineering spreads its wings and shows its intent with latest Doosan machine tool investment.

Mills CNC, the exclusive distributor of Doosan machine tools in the UK and Ireland, has supplied family-owned precision subcontract specialist – Birds Precision Engineering Ltd., with a new, large-capacity Fanuc-controlled Doosan DNM 6700XL (3-axis) vertical machining centre.

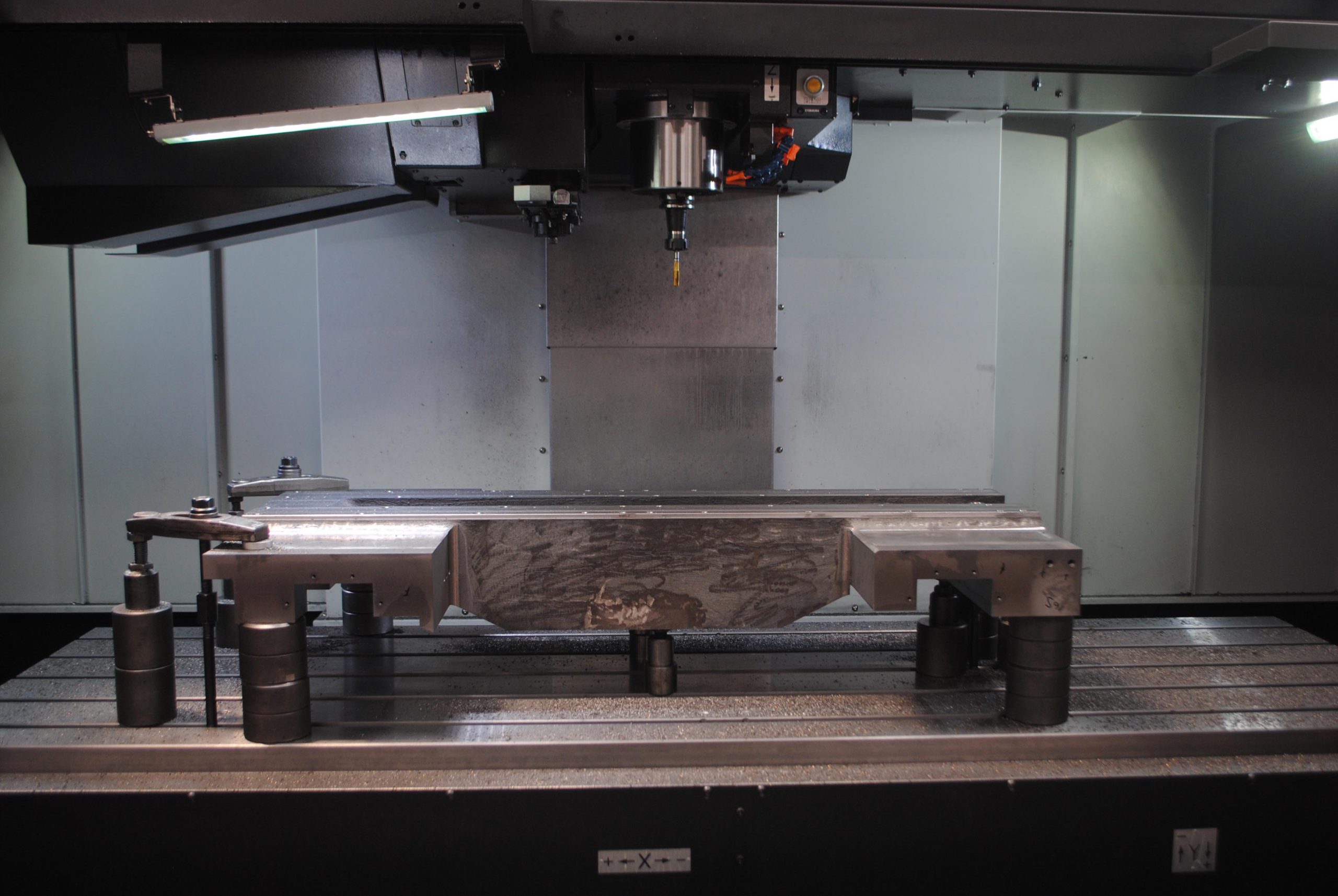

The machine which, incidentally was one of the first (if not the first) to be sold by Mills in the UK, was installed in Birds Precision’s 3,000 square foot facility in Nuneaton in September 2019 and is being used, predominantly at this moment in time, to machine high-precision, complex prismatic parts for one of the company’s (many) long-established customers based in the UK.

The parts, essentially base castings and guideways for state-of-the-art, special purpose machines, are made from cast iron and steel. The castings are large (1.2 metres long x 640mm wide) and typically weigh up to 500kg. They are machined in small batches (typically one-offs through to five- or six-offs) to exacting dimensional tolerances (0.01mm) across the part and exacting surface finishes (Ra 1.6μm).

Birds Precision supplies the parts direct to this customer and, according to owner and managing director, Chris Bird, “they have to be right first time…every time.”

The quality, lead time fulfilment and cost demands of this customer, and others like it, were amongst the main reasons why Birds Precision invested in the Doosan DNM 6700XL.

Continues Chris Bird:

“To maintain our preferred partner relationship with existing customers and win new business contracts with new and existing customers, we made the strategic decision to upgrade our machine tool capacity and capabilities.”

As a consequence the company’s machine tools that were being used to machine the large guideway parts were soon in the spotlight.

Continues Chris Bird:

“We had been using Herbert DeVlieg horizontal jig mill borers to machine these types of parts.

“Although these machines, despite their age, were still capable of delivering the accuracies required – it was becoming increasingly difficult to source spare and replacement parts for them.

“We realised that this situation would only become more acute over time and so we decided to search the market for an alternative.”

Giving youth a chance

The machine tool decision-making process was designed and implemented by consensus – with a number of the company’s younger members of staff playing the lead role in contacting machine tool suppliers and drawing up a shortlist of potential machine tools that could meet the company’s immediate and future machining requirements.

Says Chris Bird:

“The future of the company lies, to a large extent, in our ability to recruit (and retain) top young talent.

“Our recently-introduced Apprentice Programme which enables our apprentices to gain valuable skills, relevant work experience and nationally recognised qualifications, is helping us meet this objective.

“Another angle to our commitment to investing in young people is involving them, where possible, in the future direction of the company and trusting them with important decisions – such as future machine tool acquisitions.”

Narrowing down the choice

Although not a Doosan machine tool user at the time staff from Birds Precision had visited Mills CNC’s stand at MACH 2018 where they had seen a number of Doosan vertical machining centres being put through their paces.

One of these members of staff was machine shop manager, Tom Bird, who says:

“Mills CNC has a good reputation in the market, and we liked the Doosan machines we saw on their stand. So much so in fact that we invited sales staff from Mills to visit us at our facility to discuss our future requirements.”

It was during these discussions that Birds Precision was alerted to the imminent introduction of the new Doosan DNM 6700XL machine – a VMC with a 2.1 metre X-axis stroke.

Explains Tom Bird:

“The technical specifications of the DNM 6700XL, including its size, rigidity and power, ticked all the right boxes for us. We also liked the machine’s competitive price, quick availability and the fact that it was backed by Mills CNC’s renowned after-sales service and support.

“Furthermore, because the DNM 6700XL is a new machine we were convinced that it would help differentiate us in the market and a provide us with a distinct competitive advantage.”

The DNM 6700XL in action

Since being installed the DNM 6700XL hasn’t missed a beat and staff at Birds Precision have been impressed with the machine’s cutting performance, especially its high stock removal capabilities and its ability to maintain high volumetric accuracy over long machining runs.

Concludes Chris Bird:

“Such is the accuracy and surface finish of the parts being produced on the DNM 6700XL that they no longer need to be ground and hand scraped.

“The DNM 6700XL represents a significant investment for us but armed with this technology we are confident about our future growth and prosperity.”

The Doosan DNM 6700XL

In addition to its large capacity the DNM 6700XL is equipped with a powerful spindle (18.5kW/15,000rpm) with 20bar through-spindle-coolant capability, a large work table (2200mm x 570mm) and an integrated thermal compensation system that minimises the effects of heat generation and regulates thermal expansion ensuring high component accuracies and process optimisation.