A significant increase in demand for high-precision machined components from an existing oil and gas customer provides the catalyst for leading precision subcontract specialist, CNC Technology, to increase its in-house turning capacity and invest in a new, DN Solutions’ box guideway lathe from Mills CNC.

Mills CNC, the exclusive distributor of DN Solutions’ and Zayer machine tools in the UK and Ireland, has recently supplied West Midlands-based, CNC Technology Ltd., a privately-owned, precision engineering subcontract specialist, with a new heavy-duty lathe.

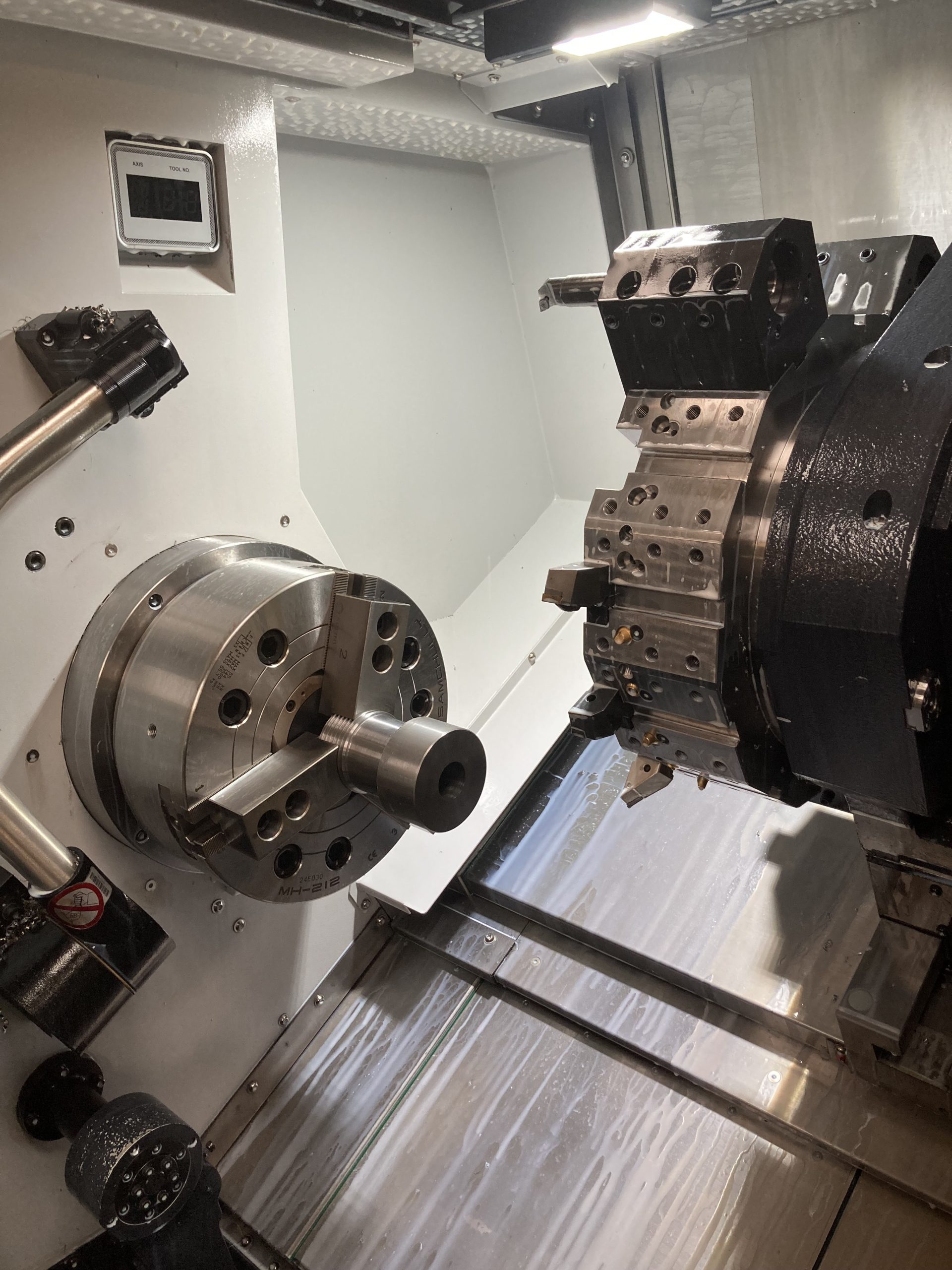

The machine, a DN Solutions’ Puma GT 3100 two-axis, box guideway lathe, was installed at the company’s 10,000sq. ft. facility in Cradley Heath in January 2025 and, since its arrival, has been put through its paces machining, predominantly, a range of complex, high-precision parts for a UK oil and gas customer supplying corrosion monitoring equipment to the Middle East.

Corrosion monitoring equipment

Oil and gas operations take place in demanding, and often unpredictable, environments that can significantly affect, over time, the performance of high-value machinery and equipment.

In order to maintain production, protect valuable assets and ensure that rigorous health and safety regulations are met, corrosion monitoring equipment is used extensively throughout the global oil and gas sector, and other refining industries.

Corrosion monitoring equipment components machined by CNC Technology are used in its customer’s retrievable and retractable access systems that are inserted into a pipeline to retrieve, in process and without affecting production, condition monitoring ‘data collection’ sensors and probes.

Increase in demand

Towards the end of 2024, one of the company’s long-standing oil and gas customers announced its intention to significantly ramp up the volume of high-quality machined components required for its corrosion monitoring systems.

These components (i.e., valves, housings/mountings etc), made from difficult-to-machine materials (Inconel alloys and superalloys) are characterised by their tight, tied-up tolerances, exacting surface finishes and complex features i.e., internal and external threads etc.

The components were previously machined in small volumes (i.e., typically one- and two-offs) and were supplied by CNC Technology to its customer as standalone parts ready for assembly.

However, the new order, designed to allow the customer to build up its stock of the most commonly used corrosion monitoring equipment components, required batch sizes of 300-off to be machined and supplied in one go.

“The advanced notification that volumes were set to increase dramatically (and virtually immediately) to batch sizes of 300-off, was clearly good news but, as we are not specifically geared up to handle large batch work, we knew that to fulfil the contract and to meet the quality, cost and lead times required, would need us to urgently review our existing in-house turning capacity and capabilities…fast.”

Steve Littlehales, Managing Director at CNC Technology

The resulting internal audit into the company’s existing turning capacity revealed that it would be difficult meeting the increased volumes without potentially affecting and compromising lead times for other customers.

“It was clear that we needed to invest in a new lathe.”

Steve Littlehales, Managing Director at CNC Technology

Relationship with Mills CNC

CNC Technology had previously, back in 2013, invested in a Doosan Lynx 220LM – a compact multi-tasking lathe with full mill and drill capabilities.

“The Lynx lathe is a great machine. It’s fast, accurate and flexible and continues to serve us well.

“As we were in the market for a new lathe, we naturally approached Mills CNC as a potential supplier for the new machine, and outlined our requirements to them.”

Steve Littlehales, Managing Director at CNC Technology

Owing to the nature of the materials being machined for the corrosion monitoring equipment components, and to help meet and, to some extent, future-proof its turning requirements moving forwards, the company decided against investing in another Lynx lathe in favour of a more powerful, box guideway machine with a longer turning length (790mm) and a larger turning diameter (525mm).

It was the cost, availability and technical specification of the Puma GT 3100, along with Mills CNC’s pre- and after-sales services and support that all helped seal the deal.

Puma GT 3100 – a closer look

The 12” chuck DN Solutions’ Puma GT 3100 is a heavy-duty machine equipped with a 22kW/2,800rpm high-torque spindle, a 12-station servo-driven turret, a live-centre (MT5) tailstock and the advanced Fanuc 0iTP control with 15” iHMI touchscreen.

The machine supplied to CNC Technology also featured a parts catcher with a conveyor, an auto tool setter and a FilterMist extraction unit.

The GT 3100 was installed at CNC Technology’s facility in January 2025 and has been in operation ever since.

“We are delighted with our latest investment.

“The GT 3100, with its rigid design and construction and its high-torque spindle has allowed us to ramp up speeds and feeds and take more aggressive depths of cut without compromising quality. As a result, part cycle times and overall productivity and process efficiencies have improved.

“We have acquired a powerful, flexible and high-performance lathe that not only meets our immediate requirements but will stand us in good stead in the future – machining jobs for new and existing customers.”

Steve Littlehales, Managing Director at CNC Technology

In addition to the corrosion monitoring equipment parts, the GT 3100 has already been used to machine pairs of precision roll forming tools (for a steel processing customer), and a range of components for a customer that manufactures can printing machines.

About CNC Technology

CNC Technology, established in 2008 and currently employing 11 highly-skilled members of staff, is a company committed to continuous improvement and, as such, regularly invests in its people, its plant and equipment, and in its processes and systems.

To maintain and strengthen its supply chain position with customers, and to ensure the high-quality of its machining services, the company regularly invests in advanced CNC machine tools.

“We have a well-resourced machine shop with 9 x CNC machining centres (3-, 4- and 5-axis machines), 6 x CNC lathes and turning centres, and a number of manual machines too (i.e., a horizontal borer and a jig borer) at our disposal.”

Steve Littlehales, Managing Director at CNC Technology

The company has an outstanding reputation in the market for the quality of its machining services and for a business approach based on honesty, integrity, transparency and trust.

In addition to high-end milling and turning, the company is recognised for its small batch machining expertise, and for its reverse engineering skills and capabilities which have resulted in it winning a number of different and more esoteric machining jobs over the years.

These have included machining and supplying vintage aircraft replacement parts (wing spars, fuselage, landing gear, cockpit etc.), for Supermarine Spitfires, from original drawings and made from original (1930’s and 1940’s) aircraft grade aluminium alloys and S154, a nickel-chrome- molybdenum steel alloy.

“We recognise that, despite our long-term relationships with many of our customers, ‘we are only as good as our last job’, and that’s why we make sure that every job we handle is the best it can possibly be.

“The latest investment in the Puma GT 3100 will help us keep our promise to customers; to supply them with high-quality, competitively-priced and ‘right first time…every time’ machined components.”

Steve Littlehales, Managing Director at CNC Technology